Whether it’s a friendly game on a neighborhood court or a broadcasted professional match, the heart of basketball is a reliable ball. And though it may seem like a simple object, it can be subject to innovation. Wilson, the company that produces the official NBA game basketball, has introduced what could be the future of sports gear—a 3D-printed airless basketball prototype. While it has a futuristic appearance, the goal is for it to look, feel, and bounce like a regular ball.

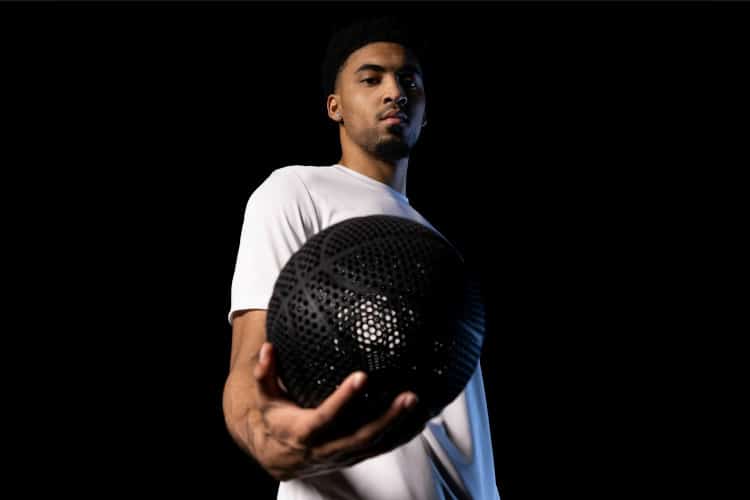

The “airless” part refers to how this ball doesn’t need to be inflated. It keeps its spherical shape without having to continually be blow up. And best of all, its unique structure and research-grade materials replicate the bouncing capabilities of a regular basketball. “This is a ball unlike anything we’ve ever seen designed to play like the basketballs we’ve always known,” says Wilson. The surface of the prototype comprises a lattice of small hexagonal holes that allow air to pass through. The eight-panel seam structure present in the model used in NBA games allows it to resemble a traditional basketball.

To create the prototype, the teams from Wilson Labs collaborated with General Lattice, who provided computational design services; DyeMansion, who gave it its black color and finishing touches; and EOS, a 3D-printing solutions company whose clients are mostly aerospace and medical companies, but was game for this project.

Unlike other 3D-printing machines, EOS took a bed of white powdered resin and hardened it by laser, producing thin stacked layers that allowed the final product to be extremely detailed. “The first-of-its-kind 3D-printed ball is truly playable, nearly fitting the performance specifications of a regulation basketball, including its weight, size, and rebound (bounce),” Wilson states.

The 3D-printed basketball made its debut during the first round the 2023 Slam Dunk contest, as it was used by Houston Rockets player Kenyon Martin Jr. Its functionality was put to the test while simultaneously adding to the theatricality of the competition by arriving in a glass box. The drama was heightened even further by its coloration matching the player’s black uniform. Though it was used during an NBA event, the league won’t make the switch from leather-based to 3D-printed balls for the time being, nor will this innovative new ball be hitting store shelves any time soon.

“There’s still work to do before it’s ready for courts around the world, but we’re thrilled by the possibilities this ball represents,” the company states. “Possibilities for other sports and future Wilson products, revolutionary sustainability through additive manufacturing and so much more. This is innovation made to push boundaries and open imaginations.”

Wilson, the company that produces the official NBA game basketball, introduced a 3D-printed airless basketball prototype.

“The first-of-its-kind 3D-printed ball is truly playable, nearly fitting the performance specifications of a regulation basketball, including its weight, size, and rebound (bounce),” Wilson states.

Ver esta publicación en Instagram

The 3D-printed airless basketball made its debut during the first round of the 2023 Slam Dunk contest, as it was used by Houston Rockets player Kenyon Martin Jr.

Wilson: Website | Instagram | Facebook

h/t: [Hypebeast]

All images via Wilson.

Related Articles:

Student Designs 3D-Printed Robot Fish That Filters Microplastics From Water

This Guy Designs Custom 3D-Printed Helmets for His Cat and It’s Adorable

The World’s First 3D-Printed Steel Bridge Opens in Amsterdam

Indiana Cheerleaders Save March Madness Basketball Game With Expert Stunt